The production of Manila rope in The Philippines involves the addition of cordage oil to the fibers in preparation for being twisted into rope. This high viscosity mineral oil is very light. However, the lighter the oil, the more the oil smells, yet the easier it is for the oil to absorb into the rope fibers.

The cordage oil doesn’t go away, but the oil will dry into the rope and that’s when the smell dissipates.

Rope from The Philippines that is made in the spring, when it’s very humid, will have a stronger smell. The humidity prevents the oil from drying into the rope efficiently. Rope made in the drier months will not smell as much because the oil has dried into the fibers faster.

If the rope mill is using a batch of fibers that is dry, it means more cordage oil needs to be added prior to production. Dry fibers that are heavily oiled in a high humidity month can result in a very smelly rope when the oil smell mixes with the fiber smell.

Better fibers means less oil is needed to make them smooth and lay properly. We do offer this as a product called Ultra Manila, which we sell in 1" and 1 1/2" diameters.

Easy. You simply put the total length of rope you need into the "Qty" field and once you are done selecting all of your items, go to your cart and checkout. You will be asked to enter your billing and shipping information.

Once you have finished entering in the data, you will then be asked to select the shipping method. The next step will ask you if you want to create an account to help you track your current and past orders. It is this section where you will be able to add notes to the order.

Use this text box to enter any cutting instructions you need. Keep in mind that on large order where there are a lot of cuts that need to be done, one of our estimators will call you to go over the order and explain any additional cutting charges that may be applied. If you have any questions, please feel free to call us at (419) 873-8300.

We are working on making this process easier and will let you know when that time comes.

Believe it or not, we get this question quite often. The answer is yes. When you order a length of rope you can expect to receive one section in that length. However, some of our ropes are limited by spool length. The rope items on our website list the spool lengths available. If, for instance, you order 700 ft of a rope that is sold in 600 ft spools and 1200 ft spools, you will receive a 600 ft spool and a coiled section of 100 ft. If you have questions about how your order would be shipped, please give us a call and we’ll happily answer this question for you.

If you would like to have the rope cut into several pieces, please follow the instructions in the above question concerning multiple lengths. Even though the majority of our rope is priced "by the foot" it is not cut into foot increments.

However, if you have a job that requires a lot of cutting in smaller sections, please call us for pricing at (419) 873-8300.

The answer is yes. However, we process these requests as a regular order. We ask that you place an online order for the rope you are interested in and select a quantity of 1 foot or the length you desire for sample size. Standard shipping rates apply.

No. Our online shipping isn't set up to compute the extra charges for shipping to this location. If you would like a shipping quote to your location outside the United States, please e-mail us and we'll let you know what we can do to help you.

We get calls for this every day. As much as we would like to help out, in order to be fair to everyone, we don't donate to anyone.

Cut-to-length rope is not returnable. If you’d like to return a new, unused spool of rope or hardware item(s) please contact us at (419) 873-8300. A 25% re-stocking fee will be applied to the refund of any returned spools of rope and/or hardware items. The customer is responsible for return shipping charges

Absolutely! Feel free to stop by and pick up your order and tour the shop if you wish. We are located at 1650 Waters Edge Dr. in Perrysburg, Ohio.

Driving South on I-475 / US 23 toward Dayton:

- Take exit 2 for OH-25 (Dixie Hwy.)

- Turn right onto OH-25 (Dixie Hwy.)

- Take a left onto Jefferson St. at the first light

- Turn left onto Waters Edge Dr.

- Knot & Rope Supply is on the left

Driving South on I-75 toward Dayton:

- Take exit 192 for I-475 / US 23 N

- Take exit 2 for OH-25 (Dixie Hwy.)

- Turn left onto OH-25 (Dixie Hwy.)

- Take a left onto Jefferson St. at the first light

- Turn left onto Waters Edge Dr.

- Knot & Rope Supply is on the Left

Driving North on I-75 toward Toledo:

- Take exit 192 for I-475 / US 23 N

- Take exit 2 for OH-25 (Dixie Hwy.)

- Turn left onto OH-25 (Dixie Hwy.)

- Take a left onto Jefferson St. at the first light

- Turn left onto Waters Edge Dr.

- Knot & Rope Supply is on the left

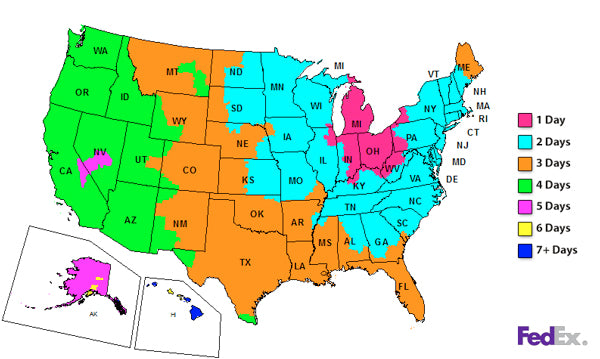

As of right now, all orders placed on the website will be shipped by FedEx Ground or UPS. Below is a map that illustrates approximate transit times for FedEx Ground leaving from our location.

Yes, we do. Our standard cut off time to accept overnight or 2-day orders and ship them the same day is 1:00pm EST. Please be aware that CUSTOM orders requiring custom cuts, splicing or fabrication work may not go out the same day even if they make it in by the cutoff time. This is due to the additional production time necessary to make up these items.

If your order is production critical and you need it shipped right away for an expedited delivery please call us here at (419) 873-8300 ex. 1 and our customer service department will be happy to help you.

PLEASE NOTE: UPS and FedEx does NOT count the weekend (Saturday & Sunday) in their transit times for expedited delivery. For Saturday delivery, you must call our customer service to receive the shipping quote for Saturday Delivery options.

The rope products on our website that are noted as being "Made in the USA" are manufactured here in the good 'ol USA. Depending on availability and/or quality of the yarn, the fiber may be sourced globally or domestically.